Air Force, MSHA Find Ways to Free Workers from the Burden of Paper

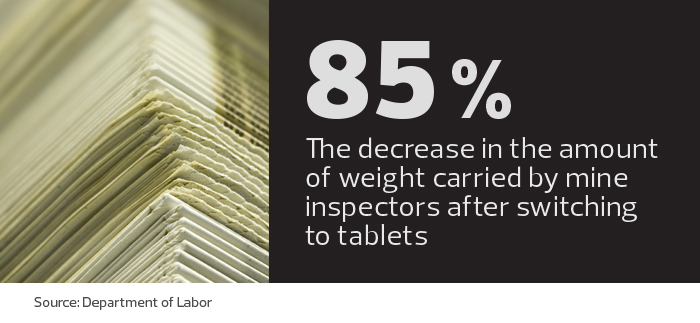

When the Department of Labor’s Mine Safety and Health Administration issued new tablets to its mine inspectors, the mobile devices not only made them more productive, but also lightened their load.

Previously, when inspectors entered mines, they each carried a bulky 8- to 9-pound laptop, a digital camera and a bunch of paper products: a notepad or clipboard, maps, documentation from previous inspections or citations — even an 800-page, 3-pound Code of Federal Regulations.

Earlier this year, the MSHA replaced all that with a 2-pound Microsoft Surface Pro, which inspectors can use to jot notes, fill out forms, shoot pictures or video, and digitally access documentation and maps, all in one device.

“The end result is an application that improves inspector efficiency, productivity and consistency,” says David G. Zatezalo, assistant secretary of labor for mine safety and health, who oversaw the project.

Like most workplaces, federal agencies pursue the holy grail of a paperless office. In 2011, an executive order required that agencies maintain all permanent records in electronic format by 2019. The transition is not complete, but many agencies already benefit from going paperless.

The National Archives and Records Administration’s most recent annual report states that 79 percent of agencies manage all emails electronically rather than printing out and filing paper versions, and that 82 percent scan permanent records to reduce storage costs.

For example, the Air Force’s Air Mobility Command (AMC) uses tablets to reduce the load for pilots who previously had to carry heavy flight bags filled with paper documents on their aircraft. And the National Heart, Lung, and Blood Institute (NHLBI) uses digital tools to speed up workflows that used to be based on paper.

SIGN UP: Get more news from the FedTech newsletter in your inbox every two weeks!

Mine Safety Experts Use Tablets to Streamline Inspections

In addition to triggering a decrease in paper use in general, tablets and mobile applications benefit a mobile workforce whose members don’t want to carry large amounts of paper to remote locations.

“Tablets are good for anyone who consumes information, and in some cases, if users are generating information and doing mine safety, for example, entering information by selecting off menus is easy to do,” says Craig Mathias, principal of the Farpoint Group, an advisory firm specializing in wireless and mobile technologies.

MSHA, which oversees roughly 13,000 mines across the U.S., inspects each underground mine four times a year and each surface mine twice a year to ensure they comply with health and safety regulations. The agency has deployed about 1,500 Surface Pros to mine inspectors and enforcement staff nationwide.

Inspectors used to take handwritten notes during an inspection. When they returned to their offices, they would type up their reports and scan their paper notes into an 18-year-old application on their laptops. They also manually uploaded photos from their digital cameras onto the laptops over a VPN or a wired internet connection.

The tablet, combined with a new custom mobile application called the Mobile Inspection Application System, or Mobile IAS, streamlines the entire process, allowing users to work faster and more efficiently, Zatezalo says.

During a site visit, inspectors can take notes on the tablet with a digital pen, a physical keyboard or the virtual keyboard that appears on the Surface screen. The Mobile IAS on the tablet offers an intuitive user interface that features prepopulated forms, making it easy for inspectors to fill out information via the touch screen, he says.

With the tablet and app, they can take photos and video as supporting evidence for their reports. They can also quickly search through digital copies of the regulations book or previous inspections and citations.

Air Force Cuts Costs with Electronic Flight Bags

The AMC, which provides airlift and aerial refueling for the armed forces and conducts humanitarian support missions, began pursuing its Electronic Flight Bag (EFB) initiative in 2010. Since then, it has equipped 18,000 air crew members with Apple iPad devices.

In the past, when crew members arrived at their squadrons, each person received a bag full of books weighing as much as 120 pounds to carry on board the aircraft. (The number of crew members per mission varies, but it’s always more than one person.)

Now each crew member receives his or her own iPad that contains all the paper documentation in PDF format. The material includes technical orders that cover every single nut, bolt or rivet on an aircraft, plus instructions and manuals on how to operate an aircraft, says Master Sgt. Joseph Pinkerton, command C-5 evaluator loadmaster and a project manager of the EFB program.

It’s more information than they could carry in the old flight bag. “We are able to reduce hundreds of thousands of pages to a single electronic device,” he says.

The use of the iPad reduces aircraft weight and results in $780,000 in fuel savings per year. The move also cuts $3.7 million annually from the cost of printing and distributing paper, says Col. Terrence Adams, AMC’s CIO and director of communications.

It took seven years to deploy the devices because IT staff needed to build applications, test the tablets thoroughly and ensure that the devices and apps met users’ needs and stringent cybersecurity requirements, Pinkerton says.

The command, headquartered at Scott Air Force Base in Illinois, began piloting the EFB program in 2012, rolling out iPad devices to specific units with a wide array of aircraft, people and missions. That gave AMC a good sampling to fully test the devices, Pinkerton says.

Initially, crews kept all the paper on the aircrafts in case the tablets failed.

“Now, we are 100 percent confident of the devices,” he says.

Air crew members regularly download updates to reference materials and applications through a Wi-Fi network at their units or through a tethered wired connection, says Master Sgt. Troy Wilkerson, the EFB information system security manager.

AMC did not have to provide much training on the iPads, Pinkerton adds: “The learning curve is minimal.”

NHLBI Develops Electronic Memo System to Save Time

The National Heart, Lung, and Blood Institute started its paperless journey about five years ago, when Dr. Gary Gibbons came on board as the agency’s director.

Gibbons instructed agency employees to eliminate as much paper as possible and use the money saved for scientific pursuits, says Alastair Thomson, NHLBI CIO.

At the time, paper-based memos that needed approval were hand-delivered from one building to another on the National Institutes of Health’s 300-acre campus. Some had to be delivered to offsite buildings as far as eight miles away.

“People would submit a memo for approval, and many times, they’d have no clue where it was. It was an enormous waste of time to find out who had it and the status of it,” Thomson says.

To develop an electronic memo system, Thomson and his IT team surveyed users to better understand their needs. Within 18 months, they launched a custom-built, web-based app called Tracking Requests and Correspondence (TRAC), which allows users to electronically send memos or contracts for approval.

The system handles anything that requires budget approval, such as technology purchases, as well as human resource–related items such as telework agreements. Scientists use the app to evaluate grant applications from external researchers and to have their own research approved for publication.

Three virtual servers within NHLBI’s data center host TRAC: One houses an open-source workflow engine, the second hosts a database and the third runs the app’s business logic, Thomson says.

Employees, especially executives and members of the acquisitions team, were used to physical signatures on paper, so they struggled with an electronic system at first, he says.

To make them more comfortable, the IT staff added a feature that allowed users to generate a PDF showing dates and times of all approvals.

“That made a huge difference. We made it more familiar to them, and it gave them a level of comfort,” he says.

Overall, the electronic memo system speeds up approvals, improves productivity and reduces costs.

“We no longer run around looking for the paper,” Thomson says. “It’s made life better for the staff.”