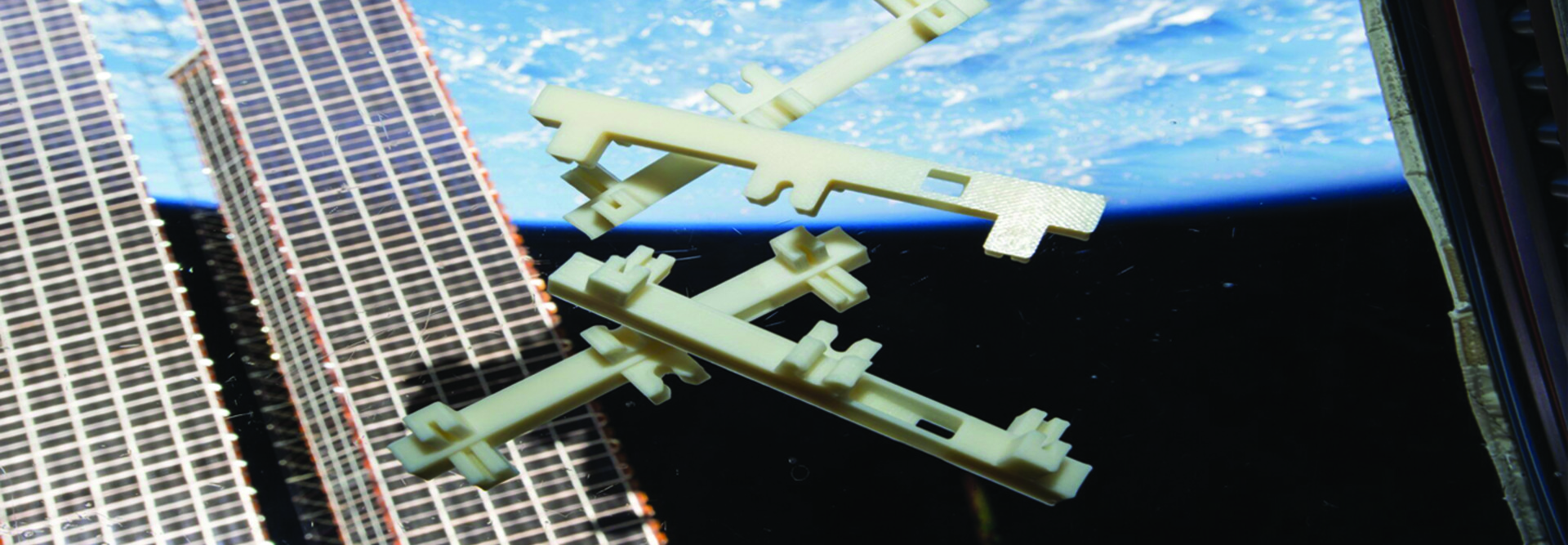

NASA’s 3D-printing program began with making tiny wrenches and may end up building infrastructure on the moon. In between those moments, however, astronauts aboard the International Space Station are testing technology designed to make the printing process more efficient.

The space station is currently home to two 3D printers, one known as the Refabricator and another called the Additive Manufacturing Facility (AMF). A third device, the Recycler, is designed to recycle used material to save room and weight on the ISS, much like the Refabricator. Each works in a slightly different way, and astronauts are trying to determine which works best.

In addition to basics such as tools and small parts, NASA hopes that eventually the 3D printers will be able to print items that are safe for food and medical use, and someday — once the planned Artemis 1 mission is complete — could even use moon dirt as printing material.

“You want to recycle what materials you have without having to take everything with you,” says Corky Clinton, associate director for the science and technology office at NASA’s Marshall Space Flight Center in Huntsville, Ala. “You don’t want to carry 1,000 spoons to Mars.”

NASA’s first 3D printer arrived on the ISS in 2014. It joined a traditional 2D printer that astronauts use to print out mission-critical documents and personal documents such as family photos, as featured in a 2018 “Feds in the Field” video.

Recycling 3D-Printed Material Creates a Regular Supply of Feedstock

The AMF was part of a technology demonstration to see how well printing worked in microgravity. The photo of smiling astronaut Butch Wilmore holding up the small wrench printed on board the ISS remains an iconic image of the In-Space Manufacturing program, Clinton says.

But that printer needed fresh material to create its tools. Sending that up to the ISS is costly; storing it takes up valuable space. NASA began researching ways to recycle plastic already on board the space station, including plastic packaging, 3D-printed tools that are no longer needed and other plastic waste.

The first recycling printer sent to the ISS, the Refabricator, has been on board for about a year. It was designed to recycle 3D-printed plastic into parts and tools that are then sent back to Earth for analysis to see how the recycling process affects the basic structure of the plastic.

Currently, astronauts are testing only the bonding properties of the recycled material; an anomaly is preventing them from further demonstrations of the print and recycling functions, Clinton says. The Refabricator will be coming back to Earth in December for a comprehensive evaluation.

NASA Moon Missions May Rely on Recycled Plastics

While using recycled material for printing will be handy on board the ISS, it will be even more valuable during Artemis, the planned crewed mission which will put the first woman on the moon in Phase 1 and explore building capabilities for future expeditions to Mars in Phase 2.

3D printing could help future astronauts build a base on the moon, Clinton says, creating buildings, roads, landing pads and other civil engineering works — and NASA plans to use dirt from the moon itself.

Doing tests on Earth is tricky, he says, because regolith (the scientific term for moon dust) has properties that can’t quite be simulated on Earth. “It’s not just the chemical composition, it’s the shape and the size of the granular structure, the processes — including extreme temperatures, thermal cycling and impacts — by which regolith is made on the moon,” he says.

Researchers also would like to figure out how to draw oxygen and metals from regolith — especially metals, which NASA is also working out how to recycle and use in printers. “We would like to not take any feedstock with us,” Clinton says.