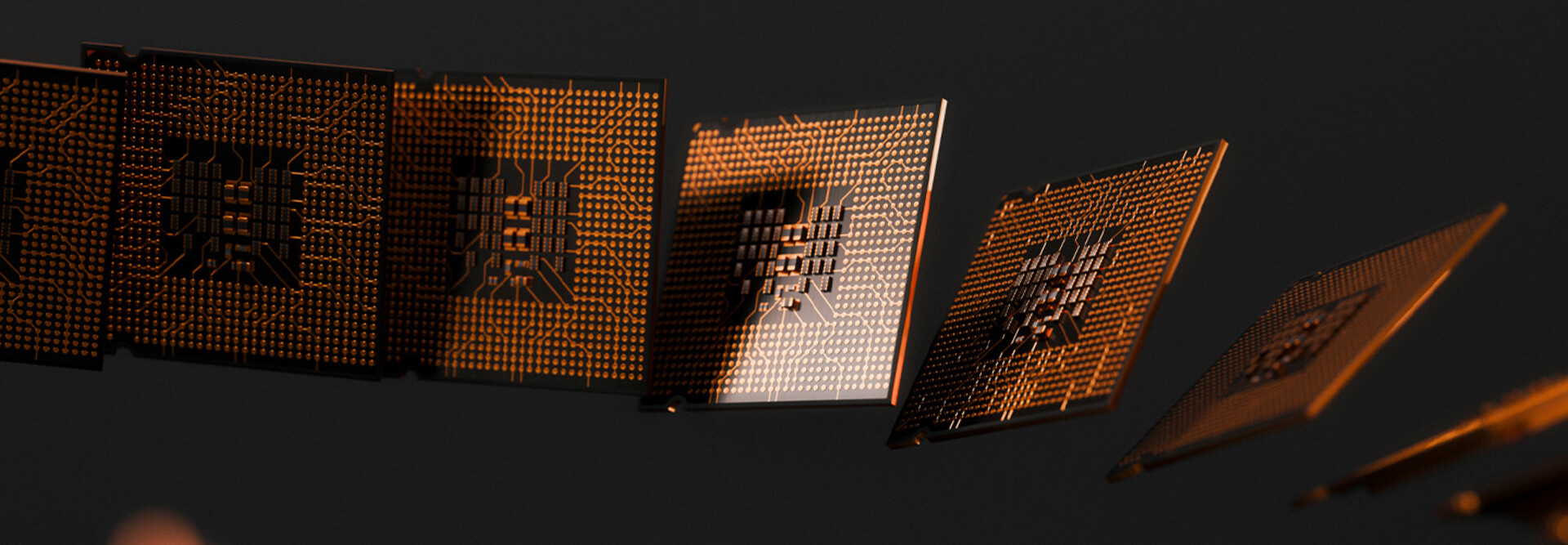

Assured Supply Chain Integrity Is the Foundation of Innovation

Semiconductors have become as essential as energy or water. Nearly 1 trillion semiconductors were sold globally in 2023, which is more than 100 chips for every person on Earth, according to the Semiconductor Industry Association’s 2024 State of the U.S. Semiconductor Industry report.

Chips span every sector of the economy: One-third go into computers; another third into communications; and demand from cars, factories and other consumer goods is fast growing, according to the 2025 version of the report.

The real risk isn’t just where those chips are made but also what we can’t see about how they’re made. Most of the world’s leading-edge production still happens overseas, and in many cases the path from raw materials to finished components crosses dozens of suppliers and borders. That complexity makes it difficult and sometimes impossible to know where every layer of a chip originated or whether any part of it passed through untrusted sources.

STUDY UP: Here are four more security trends to look for in the new year.

Federal Procurement Could Lead to a Fully Verified Ecosystem

The U.S. has moved quickly, leveraging billions in federal and private investment to build a more resilient semiconductor base, but domestic investment is only one part of the solution. The next step is to ensure that these new fabs and partners become nodes in a fully verified ecosystem.

Federal procurement can accelerate this shift. Just as agencies once set the standards for cybersecurity and cloud adoption, they can now lead in supply chain assurance.

For decades, acquisition strategies focused on “lowest price technically acceptable.” However, the lowest cost rarely delivers the highest value in terms of security or resilience. The government’s next competitive advantage lies in trust; agencies must work with partners who can guarantee full traceability and transparency.

By requiring assurance alongside performance and cost, agencies can drive demand for verified supply chains. Every contract that prioritizes provenance helps institutionalize transparency as a requirement, not an afterthought.

In practice, that means asking harder questions: Can every component be traced? Can a vendor offer products manufactured in specific geographic locations and prove that no part of the product passes through high-risk regions?

That level of verification for every part of the system from wafer to firmware is what separates resilience from risk.